Product list

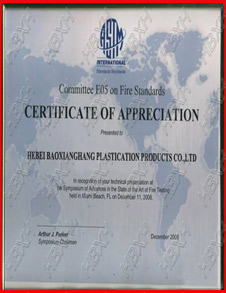

Certificate

BOPP film

1.Material: Bopp

2.Thickness: 12micron ~50micron

3.Width:

4.Length:

5.Core: 1inch/ 3inch

Character:

1) Enhances the finished products' value through high transparent and supper gloss finish; prevents lamination from being pressed, bubbled and desquamate; protects from harmful substances and waterproof, making long life storage for the printings.

2) Available in various paper and inks, and suitable for lamination even with powder paper. After being treated with corona on the surface, it is good for spot UV and hot stamping.

3) Excellent cost saving as mixing of adhesive, coating and drying processes are not required. The operation doesn't ask for special technique and the film can be used in dry and wet laminator.

4) Environmental friendly, pollution-free working environment and recycle. No hazardous to health and secure to use as no toxic gases or volatile content is emitted.

Application:

It mainly used for printing and lamination with paper and board.

It applied to books, magazines, pictures, catalogs, posters, shopping bags and other leaflets; outside coating for wrapping box for food, medicine, cosmetic, gift and liquor; drawing paper, documents, advertisements, digital printing and showing board.